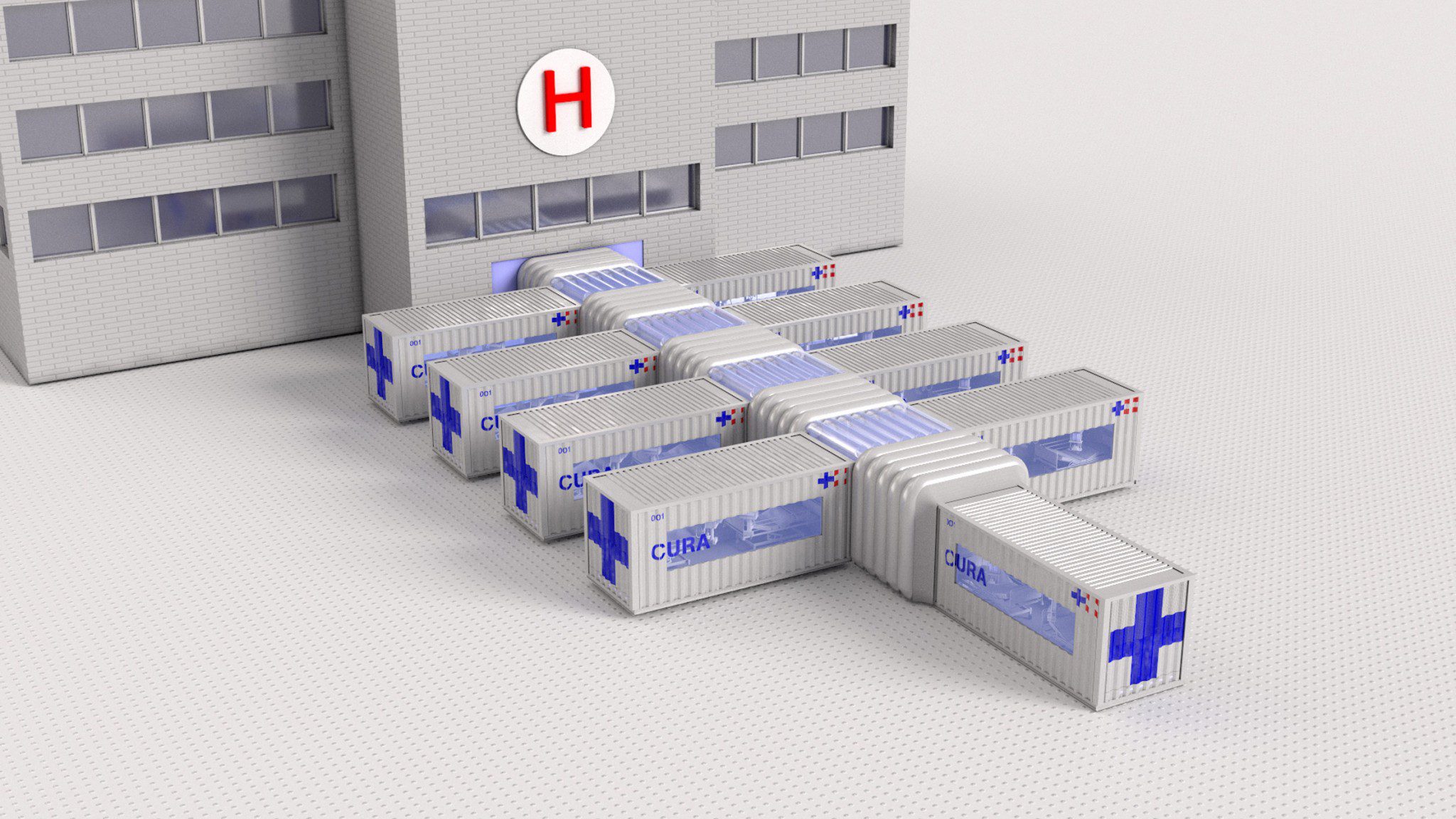

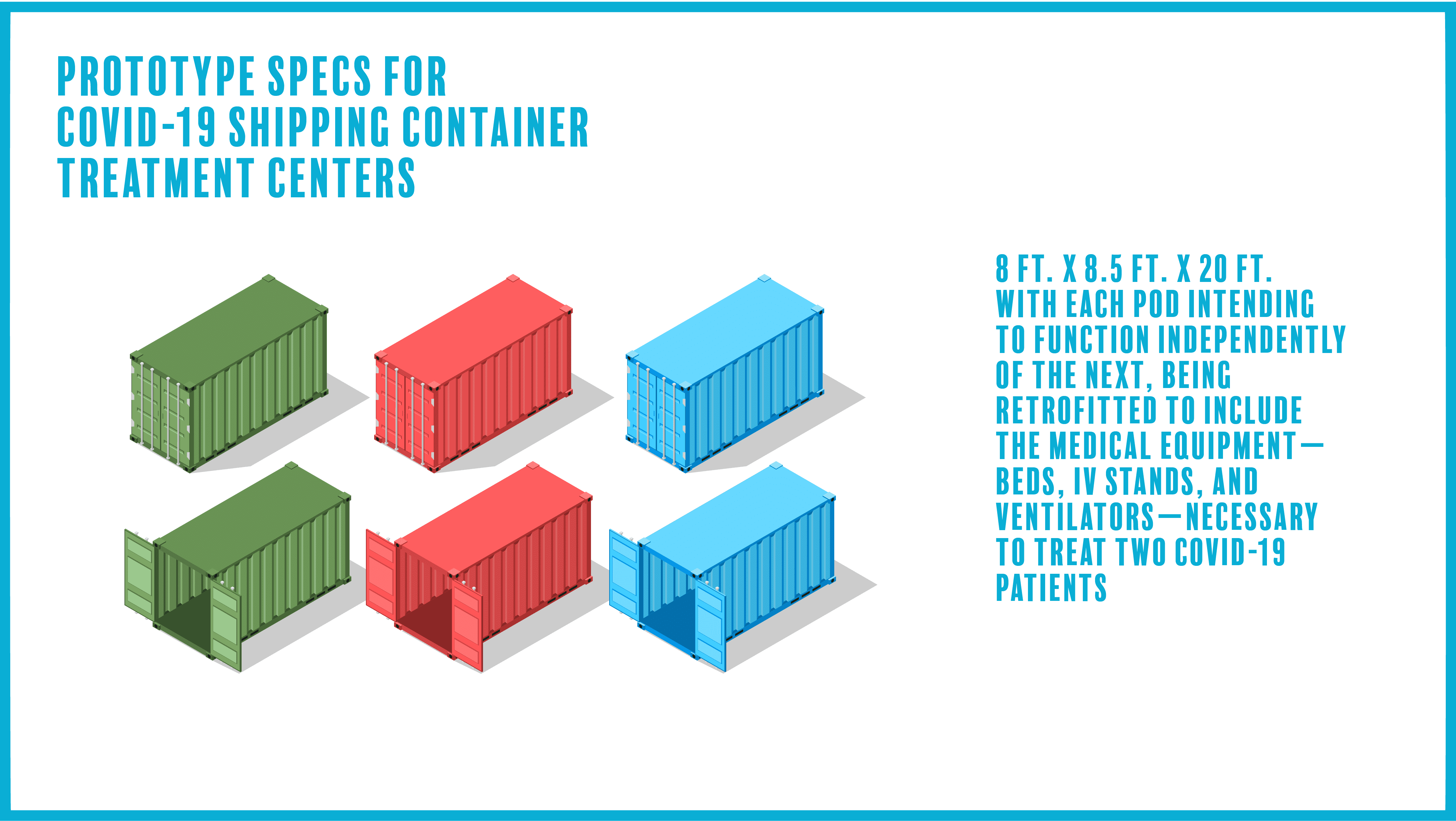

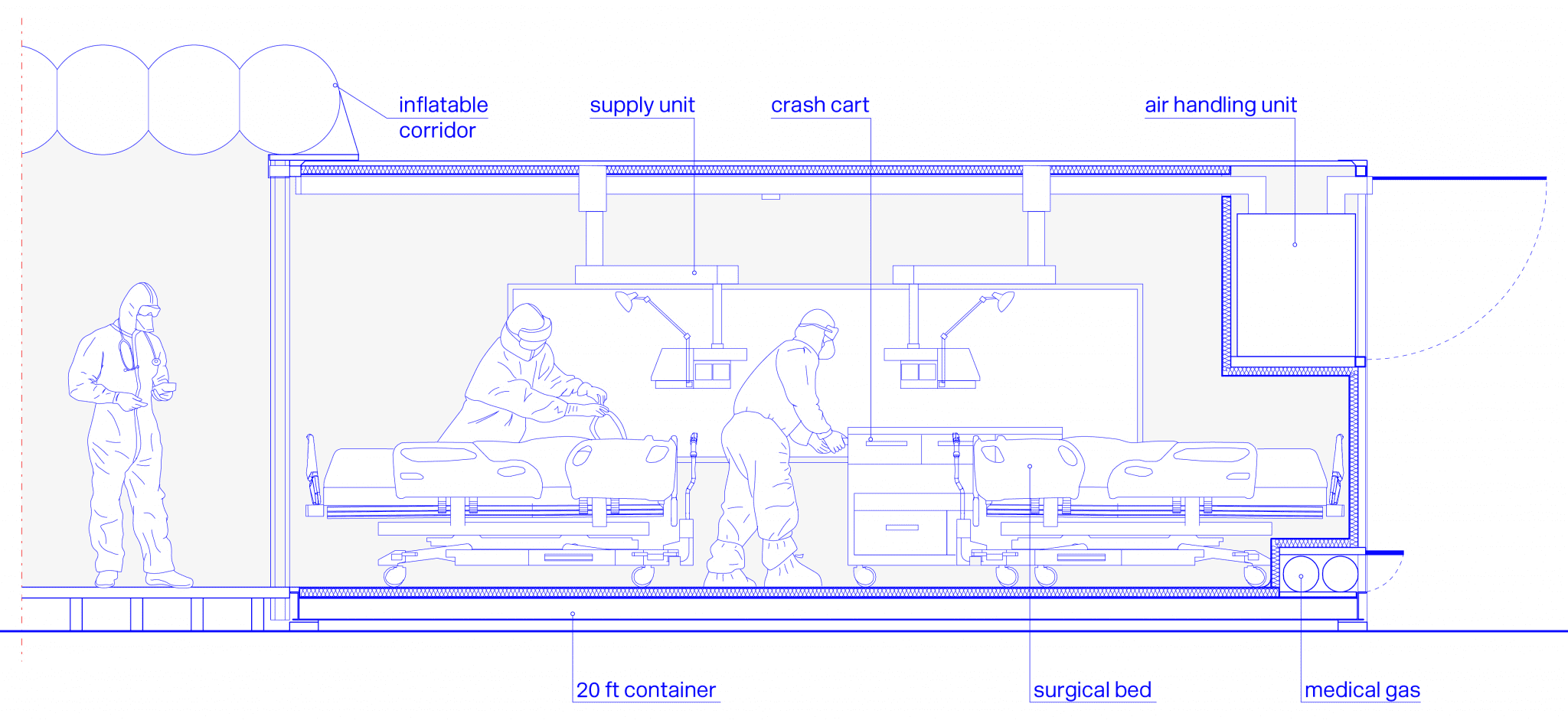

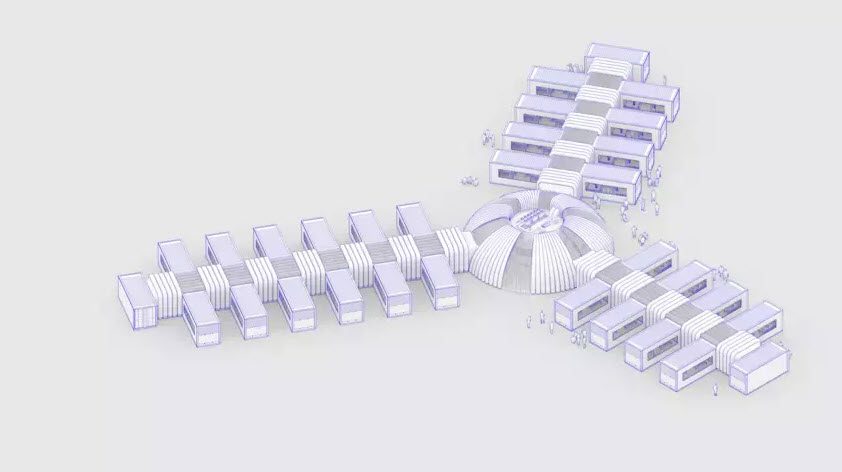

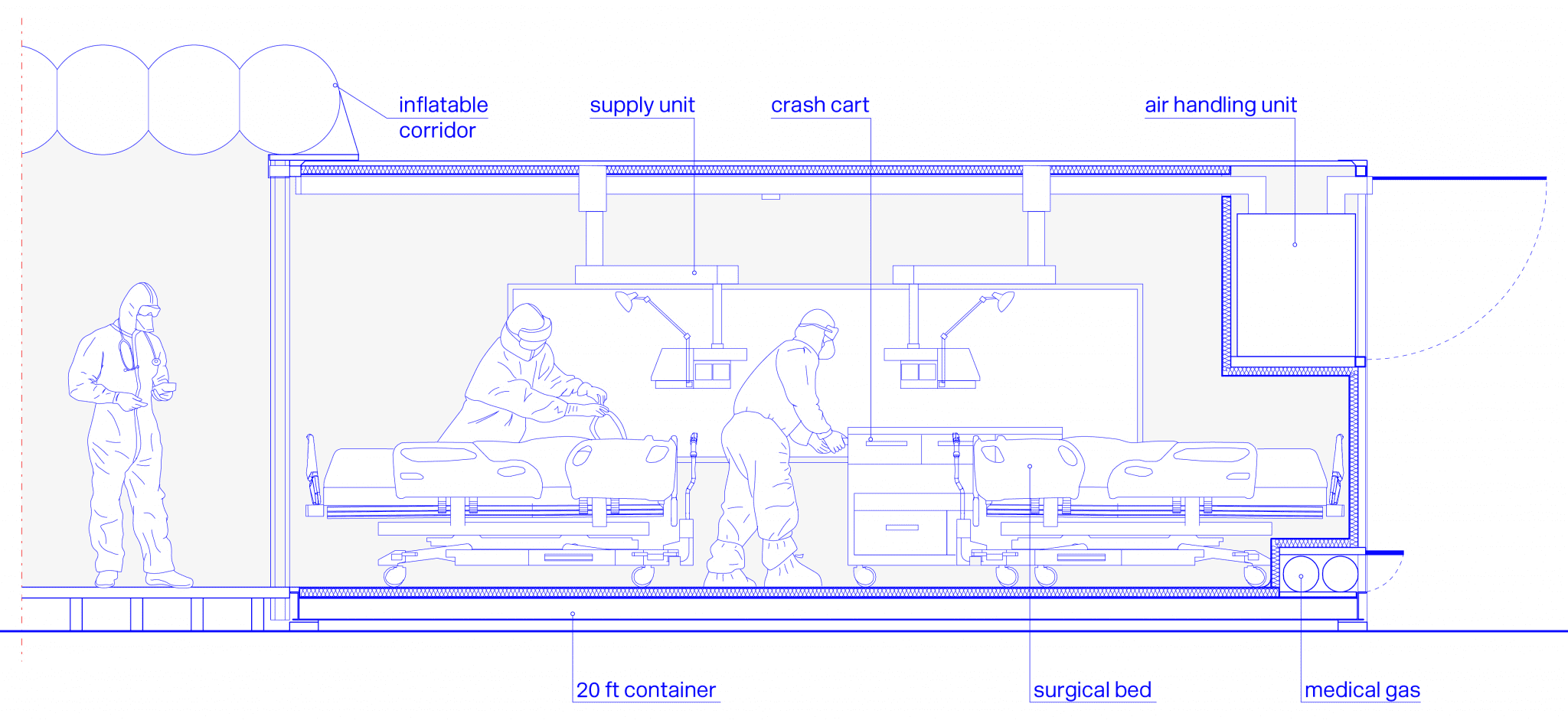

Companies and governments all over the world are developing prototypes of shipping container treatment pods. Specifically, Italian companies. Architects are building pods with a design to work as a standalone unit, or connected by an inflatable corridor structure to create larger, multi-bed clusters. [v] This specific architect in Italy building these pods estimates each one to be produced for around $100,000. Moreover, this includes all medical equipment, which is around a third of the pre-bed cost of an emergency fabricated hospital. [v]

In Macon, Georgia, state contractors will set up 18 shipping containers side-by-side in a parking lot outside Middle Georgia’s largest hospital. This is only if the city sees a surge in COVID-19 patients. Like other treatment pods, these will also be used for patients with less serious conditions, leaving the more seriously ill to hospitals. [vi]

A local builder in Gwinnett County (Georgia) says when he started seeing the need for extra room in hospitals, he knew it was his time to step in. After leasing a warehouse in Lawrenceville, GA and hiring 80 contractors in under two weeks, they’re now working 17-hour days, 7 days a week to build these treatment center pods. Each pod contains 4 patient rooms, including bathrooms connected by a corridor. [iv]

“Dr. John Wood, director of the hospital’s emergency centers, said in a telephone interview on Wednesday that the makeshift rooms will only be used if necessary, and that if they are, ‘[they will be able to] take care of (patients) just like regular hospital patients, just outside the main facility.’” [vi]

Image: CURA

Companies are building these shipping containers as precautionary measures. They are less actionable for areas where the surge of coronavirus cases hasn’t quite hit, but in order for these pods to be fully functioning there is a main component that is necessary: power. Rogers Electric completes work in multiple different sectors of business, with healthcare being one of those.

During this pandemic, some of Rogers Electric’s main priorities include finding ways to stay connected with our community and taking the steps to use our resources to help people stay socially distanced, while still being connected through technology and innovation. Head on over to our blog to see just how Rogers Electric is dedicating time and resources to the pandemic.